Tempered glass

Tempered glass

Our force, Price. Our commitment, Quality.

We specialize in laminated and tempered glass. From here our range of products in laminated glass: Lamikt®; tempered laminated glass: Lamikt® Tempikt®; laminated in Transmatt® matte and tempered glass: Tempikt®.

Always with the highest product quality and the best market price, we seek to meet the needs of our customers by providing our experience in the sector, delivering top quality product at the best prices in the market, which translates into being a company of reference in the European market of laminated and tempered glass.

We have quality controls of the highest demand that guarantee the delivery of the best product. Our team and our facilities are to meet the needs of our customers.

Tempered glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared with normal glass. Tempering puts the outer surfaces into compression and the inner surfaces into tension. Such stresses cause the glass, when broken, to crumble into small granular chunks instead of splintering into jagged shards as plate glass (aka: annealed glass) create. The granular chunks are less likely to cause injury.

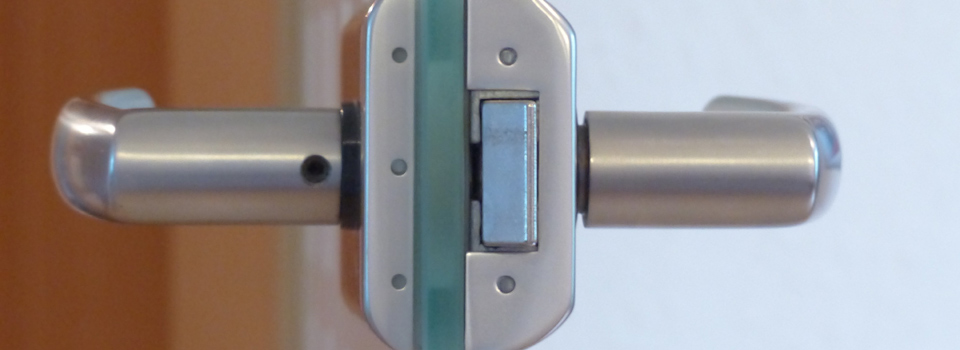

As a result of its safety and strength, toughened glass is used in a variety of demanding applications, including passenger vehicle windows, shower doors, architectural glass doors and tables, refrigerator trays, as a component of bulletproof glass, for diving masks, and various types of plates and cookware.

The term tempered glass, in addition to meaning glass that has been heat treated to increase toughness, can refer to glass that has been treated with hydrofluoric acid or other acid. The acid etches away surface scratches and imperfections to increase strength.

Toughened or tempered glass is not Plate glass (aka: Float glass, Annealed glass). These types of glass are created under completely different environments. Plate glass can cause serious, if not deadly, injuries; whereas, tempered glass was designed to sustain minimal injuries.

Properties

Toughened glass is physically and thermally stronger than regular glass. The greater contraction of the inner layer during manufacturing induces compressive stresses in the surface of the glass balanced by tensile stresses in the body of the glass. For glass to be considered toughened, this compressive stress on the surface of the glass should be a minimum of 69 megapascals (10,000 psi). For it to be considered safety glass, the surface compressive stress should exceed 100 megapascals (15,000 psi). The greater the surface stress, the smaller the glass particles will be when broken

It is this compressive stress that gives the toughened glass increased strength. This is because any surface flaws tend to be pressed closed by the retained compressive forces, while the core layer remains relatively free of the defects which could cause a crack to begin.

Any cutting or grinding must be done prior to tempering. Cutting, grinding, sharp impacts and sometimes even scratches after tempering will cause the glass to fracture. When molten glass is dripped into water, it creates objects known as “Prince Rupert’s Drops”. These glass tadpole-like objects can be hammered without damage but will shatter completely when their “tails” are even slightly damaged. This is an extreme example of the effects of internal tension.

The strain pattern resulting from tempering can be observed with polarized light or by using a pair of polarizing sun glasses.

Uses

Tempered glass is used when strength, thermal resistance, and safety are important considerations. The most commonly encountered tempered glass is that used for side and rear windows in automobiles.

A shattered driver’s side window reveals small fragments that still cling together.

It is used for its characteristic of shattering into small cubes rather than large shards and is sometimes referred to as safety glass in this context. (The windscreen or windshield is instead made of laminated glass, which will not shatter when broken.)

Toughened glass is also used in buildings for unframed assemblies (such as frameless glass doors), structurally loaded applications, and any other application that would become dangerous in the event of human impact.

“Rim-tempered” indicates that a limited area, such as the rim of the glass or plate, is tempered and is popular in food service.

Cooking and baking

Some forms of tempered glass are used for cooking and baking. Manufacturers include Glasslock, Pyrex, Corelle, and Arc International.

Manufacturing

Tempered glass can be made from annealed glass via a thermal tempering process. The glass is placed onto a roller table, taking it through a furnace that heats it above its annealing point of about 720 °C (1,328 °F). The glass is then rapidly cooled with forced air drafts while the inner portion remains free to flow for a short time.

An alternative chemical toughening process involves forcing a surface layer of glass at least 0.1 mm thick into compression by ion exchange of the sodium ions in the glass surface with potassium ions (which are 30% larger), by immersion of the glass into a bath of molten potassium nitrate. Chemical toughening results in increased toughness compared with thermal toughening and can be applied to glass objects of complex shapes.[1]

Advantages

Tempered safety glass, which has been laminated, often does not fall out of its frame when it breaks – usually due to the anti-splinter film applied on the glass, as seen in this grocery store meat case.

The term “toughened glass” is generally used to describe fully tempered glass but is sometimes used to describe heat-strengthened glass as both types undergo a thermal “toughening” process.

There are two main types of heat-treated glass: heat-strengthened and fully tempered. Heat-strengthened glass is twice as strong as annealed glass while fully tempered glass has typically four to six times the strength of annealed glass and withstands heating in microwave ovens. The difference is the residual stress in the edge and glass surface. Fully tempered glass in the US is generally rated above 65 megapascals (9,400 psi) in pressure-resistance, while heat-strengthened glass is between 40 and 55 megapascals (5,800 and 8,000 psi)

It is important to note that the tempering process does not change the stiffness of the glass. Annealed glass undergoes a similar deflection compared to tempered glass under the same load, but tempered glass can take a higher load and, therefore, deflects further before breaking.

Disadvantages

Toughened glass must be cut to size or pressed to shape before toughening, and cannot be re-worked once toughened. Polishing the edges or drilling holes in the glass is carried out before the toughening process starts. Because of the balanced stresses in the glass, damage to any portion will eventually result in the glass shattering into thumbnail-sized pieces. The glass is most susceptible to breakage due to damage to the edge of the glass, where the tensile stress is the greatest, but shattering can also occur in the event of a hard impact in the middle of the glass pane or if the impact is concentrated (for example, striking the glass with a hardened point).

Using toughened glass can pose a security risk in some situations because of the tendency of the glass to shatter completely upon hard impact rather than leaving shards in the window frame.

The surface of tempered glass does exhibit surface waves caused by contact with flattening rollers, if it has been formed using this process. This waviness is a significant problem in manufacturing of thin film solar cells. The float glass process can be used to provide low-distortion sheets with very flat and parallel surfaces.

History

The first patent on tempered glass was held by chemist Rudolph A. Seiden, born in 1900 in Austria.

Though the underlying mechanism was not known at the time, the effects of “tempering” glass have been known for centuries. In about 1660, Prince Rupert of the Rhine brought the discovery of what are now known as “Prince Rupert’s Drops” to the attention of King Charles II. These are teardrop-shaped bits of glass which are produced by allowing a molten drop of glass to fall into a bucket of water, thereby rapidly cooling it. They can withstand a blow from a hammer on the bulbous end without breaking, but the drops will disintegrate explosively if the tail end is even slightly damaged.